OUR TECHNOLOGY

Learn what's behind our clean room curtains!

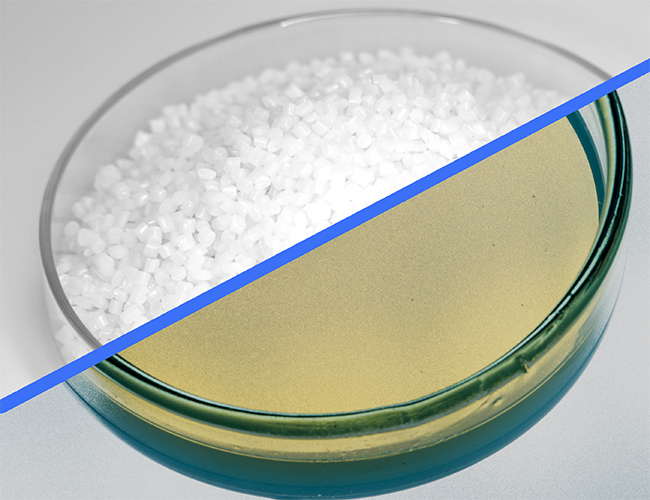

How we make a plastic-like granulate into high-purity glass.

REVOLUTIONARY GLASS PRODUCTION

Glass outperforms polymers in many applications and is unmatched in its combination of high thermal, chemical stability paired with high transparency. However, today customers often use polymers instead of glass – because glass shaping is inherently more difficult than polymer shaping. Glassomer changes that.

Conventional glass manufacturing has reached its limits. Methods like grinding, etching, laser structuring, sol-gel processing and precision glass molding all suffer from major drawbacks such as limited design space, rough surfaces, high energy requirements and low glass quality. The Glassomer process unites almost unlimited freedom of design, feature sizes across one order of magnitude, low temperature processing, smooth surfaces and high quality glass in one process.

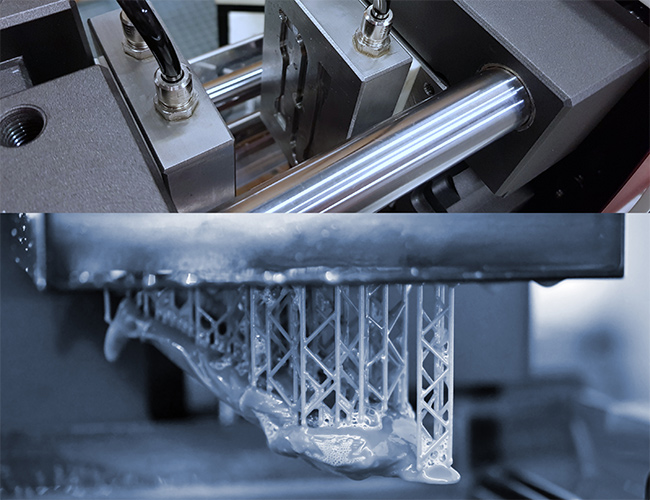

PRODUCING GLASS IN THE 21ST CENTURY THE GLASSOMER PROCESS

Process Steps

The disruptive Glassomer Technology for Glass Component Production.

High Quality fused Silica glass

Our fused silica is made from highest purity fused silica glass powders. Due our sintering process, we achieve a minimal amount of hydroxyl groups in the final glass. Our glass is highly transparent and due to our precision injection molding process, we achieve very smooth surfaces with minimal reflection losses.

UV/VIS TRANSMISSION

Our glass contains no metallic impurities and color (E’) centers below 260 nm.

-

UV-Transmission @ 200 nm: 84 %

-

VIS-Transmission @ 300-1000 nm: >92 %

INFRARED (IR) TRANSMISSION

Our glass contains a minimal amount of hydroxyl groups, comparable to commercial fused quartz.

-

IR-Transmission @ 1000-3400 nm: >90 %

FURTHER DATA

-

Bending strength: 115 MPa

-

Vickers Hardness: 980 HV

-

Therm. Expansion: 0.52 x 10-6 1/K

-

Static contact angle with water: 36 °

-

Surface energy: 60 mN/m